Lithium-ion (Li-ion) and Lithium-polymer (LiPo) batteries can cause fires. Because lithium-based batteries have a high energy density, they can hold more power and last longer than other battery technologies. As a result, manufacturers use lithium batteries in various appliances, including cellular phones, portable computers, tablets, cameras, flashlights, radio-controlled vehicles, electronic cigarettes, vaping devices, power tools, and vacuums. On a larger scale, electric vehicles and energy storage facilities use lithium batteries.

Due to their prevalence in devices, investigators often discover lithium batteries at or near the fire origin. Because lithium battery can expel burning material across a room, the investigator must consider any failed battery within a line-of-site of the origin.

Lithium batteries can be a significant ignition source because the battery not only has stored electrical energy, but the composition of the battery also contributes chemical energy. The electrolyte (liquid in Li-ion cells and gel in LiPo cells) and the lithium metal are flammable. During a thermal runaway, the battery components also provide a source of oxygen so that the battery does not need ambient air to burn.

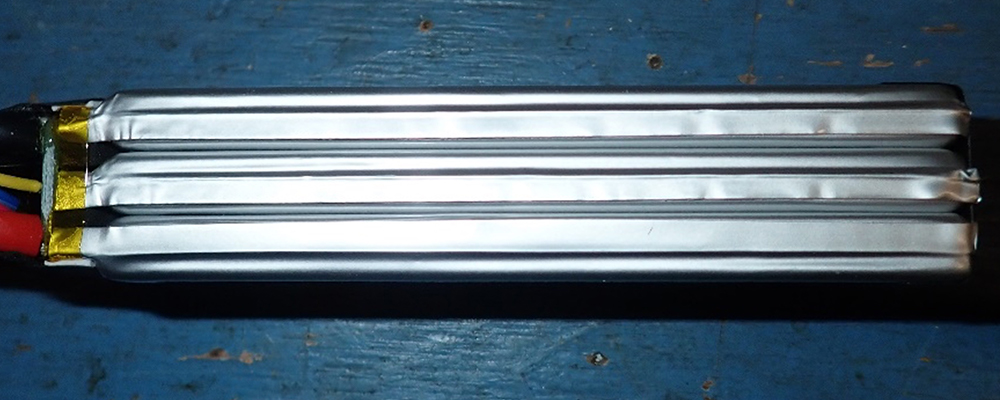

Lithium battery failures can result from manufacturing defects, physical damage, overcharging, over-discharging, external heating, or high current charge or discharge. Contributing factors include a poor design of the cell, improper application, manufacturing quality issues, improper battery monitoring and management, and improper handling and storage.

When a lithium battery fails, the results range from a cell that appears to be fine but no longer works to an explosion that expels burning material to the surrounding area. After a fire, it is not difficult to determine if a lithium battery failed. The difficulty is determining if the battery caused the fire. If the investigator cannot rule out a battery failure, they will need additional analysis to ascertain the failure mode and the contributing factors.

Although all investigations are handled based on the available information and may take a varied path, a general outline of the various stages of a battery failure investigation includes:

- Scene examination by O&C investigator identifies a potential battery failure.

- O&C interviews insured to identify the type of devices and batteries involved.

- Investigators and engineers examine the scene to identify all possible cause hypotheses and begin to rule them out. Investigators collect evidence ensuring that all battery and device remains are collected.

- The adjuster should consider authorizing the purchase of exemplars at this time to avoid obsolescence.

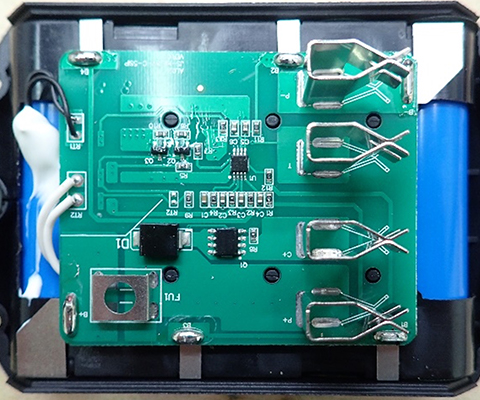

- Engineers examine the evidence, such as at the RDA lab to rule out cause hypotheses. RDA often x-rays the battery remains to determine if computer tomography (CT) scans are required.

- Engineers agree to send out select batteries for CT scanning. RDA can then interpret the CT scans to distinguish between cells that failed by external heating and cells that may have caused the fire. RDA also uses the CT scans to identify the cell and battery manufacturer and rule out counterfeit cells.

- Engineers reconvene to examine the suspect cells.

- RDA may connect instrumentation to exemplar batteries to perform charge/discharge cycle testing to determine the battery failure's contributing factors.

- While it is not always necessary, discovery documentation may be required to rule out various contributing factors.

RDA has extensive experience with lithium battery fires. We have trained origin and cause investigators that know what to look for on scene and the critical information they must gather through witness interviews.

RDA also has extensive experience with battery examination, including interpretation of radiographs (generated with our in-house x-ray equipment) and computer tomography (CT) scans. We have the instrumentation and knowledge to test exemplar batteries and devices required to identify the proximate cause of the battery failure.